Concrete hollow blocks have been used as a building material for more than a century, and in Guyana, it is the most common material in the construction of homes and commercial buildings. Made from cement, different aggregates and water, more persons have joined the trade of manufacturing concrete hollow blocks locally. However, in some cases, the units are not as durable as they should be.

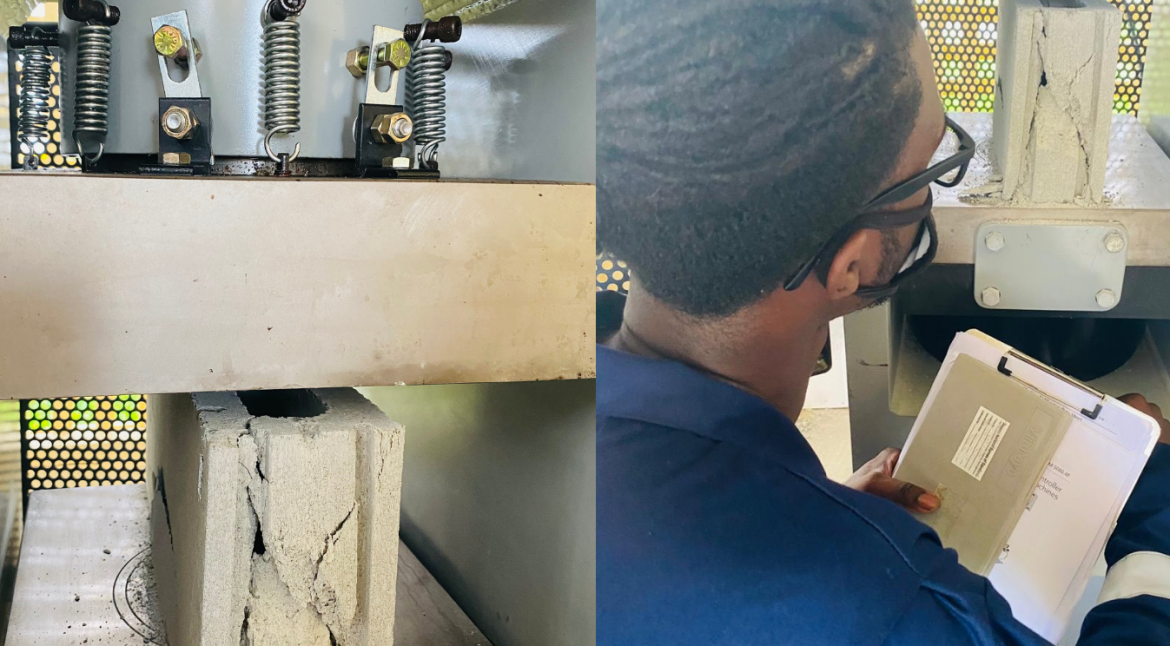

In fact, preliminary tests conducted by the Guyana National Bureau of Standards (GNBS) revealed that the majority of blocks made by some manufacturers are below the compressive strengths stipulated by the Guyana Standard Specification for Load Bearing Masonry Concrete Units (GYS 215:2003).

As a result, the GNBS recently began testing of concrete hollow blocks at its Flat 15, Sophia Exhibition Complex, Georgetown location. This helps to determine whether blocks available for construction are conforming to the requirements of the National Standard. Further, testing guides builders and manufacturers on the quality, which should be achieved for hollow blocks to be generally acceptable for use.

A minimum of one concrete block (sizes including three, four and six inches) is needed for testing to ascertain the durability of a unit. The National Standard requires that an individual unit (block) have a compressive strength of not less than 5.5 Megapascals (Mpa) (798 PSI), or the average of three units must not be less than 7 Mpa (1015 PSI). Tests are conducted within three days after samples are submitted to the GNBS.

Over the years, homeowners and contractors complained about substandard building materials available in the construction sector. Complaints indicated that a high percentage of concrete hollow blocks were broken, distorted or easily broken during normal handling, leading to losses and injury. Today, the GNBS testing service is available to block-makers as well as contractors and homeowners who want to be assured that the material is durable for their construction.

In addition to testing, the GNBS under the Product Certification (PC) Programme is capable of providing Certification to local manufacturers and block makers who would like to continually demonstrate that their hollow blocks are meeting standard requirements. Certification indicates quality and provides confidence to consumers, thereby increasing demand and sales. Interested businesses can approach the Bureau to be part of the PC Programme and use the certification mark. Importantly, for certification, a sample size of five to seven blocks would be required for testing.

Aside from outlining parameters for compressive strength and moisture content, the Standard for concrete hollow blocks has other requirements. For example, it states that all concrete hollow blocks must be free from visible cracks and other defects, which would affect their proper application, or impair the strength or performance of the construction.

The GNBS also has 19 other Construction Standards, which cover bases for design of structures, specifications for concrete drains, hollow clay blocks, steel nails, ready mixed concrete, chain link fence fabric and several building codes. Local manufacturers are encouraged to acquire and utilize these National Standards in the production of building and construction materials.

For further information, please contact the GNBS on telephone numbers: 219-0064-66 or follow us on Facebook: @gnbsgy.